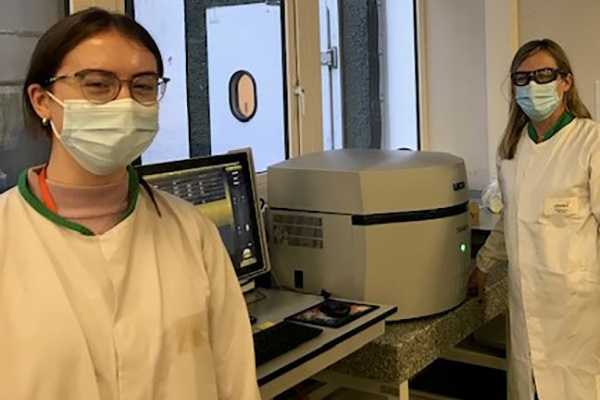

Norma is pictured with Lab Technician Doireann Harding in front of the new TGA instrument in Ballyragget

Chewing the cud with… Norma Moore

Each month, we put the spotlight on a Glanbia Ireland employee and for our January newsletter, we spoke to Norma Moore, Quality Control Manager in the Chemistry Lab at GI’s Ballyragget processing facility.

Norma joined Glanbia Ireland as Head of Quality for the Ballitore site in January 2020 after previously working in both Supply Chain and Quality for Diageo and BC Manufacturing in Kilkenny and Dublin since graduating from college. Joining the company just as the pandemic struck was a challenge at first, but the Ballitore Quality team ‘Found a Better Way’ to ensure they could carry out their tasks while keeping colleagues safe while on site. Having dealt with Glanbia Ireland’s unique products and teams in previous roles Norma was “always keen to join the company” due to the ‘Winning Together’ and ‘Showing Respect’ culture within the company.

In January 2021 Norma moved to the Ballyragget site, taking on the Quality Control Manager role for the Chemistry Lab. “2021 has been an extremely interesting year overall for me, with the Ballyragget site processing record volumes of milk and finished product this year, all of which requires testing, grading, release and the approval of new customers & specifications”, Norma told Overheard. One of the highlights of the year for Norma was working on the delivery of Project Rome and, “collaborating with other sites and departments ensures the job is both exciting and continually changing”.

“What excites me about my role is that it is everchanging! In a typical day, I pop down to the lab to meet the team first thing in the morning. After that we have our Quality calls at 9am each day to assess the current state of play in the lab and following the meeting myself and the team address any issues that are presenting themselves.” In many ways the Quality team ensures Glanbia Ireland products live up to our value of ‘The Customers Champion’. “The bar is always rising with our customers in terms of their product requirements, specifications and GMP expectations and the laboratory has a key role in meeting the contracted volumes to customers including Bel, LactoJapan, Diageo, Russia.”

The month of June is the Quality teams busiest time of year with milk intake at its peak, with this Norma credits her team of 14 who are “the single most important resource within the laboratory. They are highly skilled and work hard to ensure all testing is completed on time in full.” Outside of their prescripted roles the team are “extremely supportive of each other and ensure any new team member feels welcome and part of the team. The support for me from the team on joining Glanbia, Ballyragget this year made my transition so much easier.”

Examples of the tests that are carried out in the chemistry lab are Particle size, Hydration, pH, Sediment, Moisture, Fat, Salt, Ash, Protein, PV, FFA, Nitrates by both rapid and reference methods. New equipment is part of the ongoing improvements in the laboratory and the team continuously engage to deliver!